Cyclone Dust Collector

Cyclone Dust Collector

Product Names Cyclone Barrel Cyclone Dust Collector Cyclone Dust Separator II. Working Principle Vertical-tube cyclone dust collectors represent one of the earliest and most widely applied types of gravity-based dust removal equipment. Their dust separation mechanism relies on the rotational motion of dust-laden airflow induc…

Product Introduction

Product Names

- Cyclone Barrel

- Cyclone Dust Collector

- Cyclone Dust Separator

II. Working Principle

Vertical-tube cyclone dust collectors represent one of the earliest and most widely applied types of gravity-based dust removal equipment. Their dust separation mechanism relies on the rotational motion of dust-laden airflow induced by guide vanes upon entering the collector. Centrifugal force separates particles from the gas stream, depositing them onto the walls, while gravity and inertia direct the particles into the ash hopper.

Modern cyclone dust collectors have evolved into multiple configurations. Based on airflow entry methods, they are categorized into:

- Tangential entry type

- Axial entry type (capable of processing 3 times more gas volume at equivalent pressure drop, with superior airflow distribution)

- A standard cyclone dust collector comprises:

- Cylindrical section

- Conical section

- Inlet/outlet pipes

Key Advantages:

- Simple structure facilitating manufacturing, installation, and maintenance

- Low capital and operational costs

- Effective separation of solid/liquid particles from gases or solids from liquids

Performance Characteristics:

- Generates centrifugal force 5–2,500 times greater than gravity, significantly outperforming gravity settling chambers

- Typically removes particles >0.3μm; multi-cyclone parallel systems achieve 80–85% efficiency for 3μm particles

- Specialized versions constructed with heat-resistant (to 1,000°C), abrasion- and corrosion-resistant metals/ceramics can operate under extreme conditions (up to 500×10⁵Pa pressure)

- Recommended pressure drop range: 500–2,000Pa (optimizing technical and economic balance)

Related products

Cyclone Dust Collector

Product Names Cyclone Barrel Cyclone Dust Collector Cyclone Dust Separator II. Working Principle …

Pulse-Jet Baghouse Dust Collector

Basic Introduction: Pulse-jet dust collector consists of ash hopper, inlet and outlet ducts, filtration chamber…

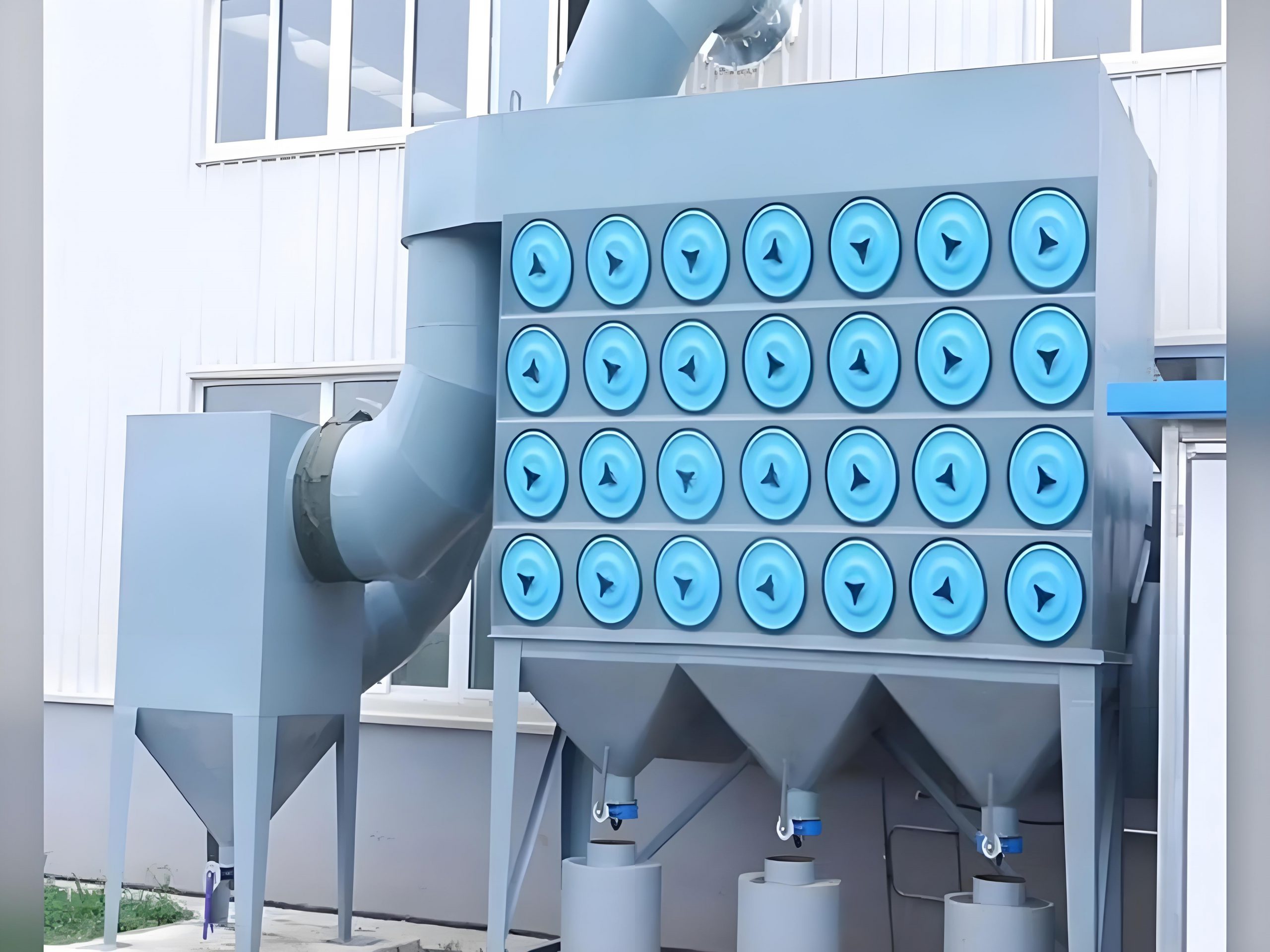

Cartridge Dust Collector

A cartridge dust collector is a type of dust removal equipment that uses filter cartridges as the …