Zeolite Rotor Concentrator with Catalytic Combustion

Zeolite Rotor Concentrator with Catalytic Combustion

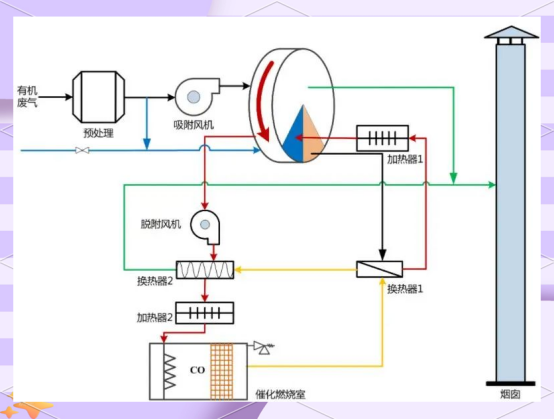

Zeolite Rotor + Catalytic Combustion is a combined waste gas treatment process primarily used for treating large-volume, low-concentration organic waste gases. This process integrates the adsorption and concentration capabilities of the zeolite rotor with the high-efficiency purification of catalytic combustion, offering advantages such as excellent treatment efficiency, low energy consumption, and simple operation.

Catalytic Combustion is a highly efficient purification technology that enables the flameless combustion of organic waste gases at relatively low temperatures, decomposing them into carbon dioxide and water under the action of a catalyst.

In a catalytic combustion system, noble metal catalysts reduce the activation energy of the reaction, allowing organic waste gases to combust at a lower ignition temperature, thereby enhancing purification efficiency.

The Zeolite Rotor + Catalytic Combustion waste gas treatment process has the following characteristics:

- Capable of handling large airflows with low concentrations: The zeolite rotor concentrates low-concentration exhaust gases into high-concentration streams, significantly reducing treatment difficulty. The catalytic combustion unit then efficiently purifies the high-concentration exhaust.

- Suitable for exhaust gases free of S, N, Cl, F, and other halogens: These elements may form harmful substances at high temperatures, but catalytic combustion effectively prevents such occurrences.

- Energy-efficient: Catalytic combustion operates at relatively low temperatures, reducing energy consumption.

- Easy operation: Both the zeolite rotor and catalytic combustion unit feature modular designs, facilitating installation, commissioning, and maintenance.

The zeolite rotor + catalytic combustion waste gas treatment process offers extensive advantages in practical applications.

Firstly, this process is suitable for treating large-volume, low-concentration organic waste gases, effectively purifying pollutants to meet environmental emission standards. Secondly, the combination of zeolite rotor adsorption-concentration technology and the high-efficiency purification of catalytic combustion ensures high performance, stability, and reliability, meeting diverse waste gas treatment demands. Additionally, this process features low energy consumption, simple operation, and easy maintenance, helping enterprises reduce operating costs and improve economic efficiency.

In practical applications, the zeolite rotor + catalytic combustion process requires customized design and configuration based on different waste gas compositions and treatment requirements.

- First, the appropriate zeolite rotor model and specifications must be selected according to parameters such as gas flow rate and concentration to ensure optimal treatment efficiency.

- Second, the catalyst and catalytic combustion unit should be chosen based on the waste gas composition and properties to guarantee stable and reliable treatment performance.

- Furthermore, the entire system must be properly designed and arranged to ensure smooth and efficient waste gas treatment.

This process demonstrates strong adaptability and effectiveness, making it a highly competitive solution in industrial waste gas treatment.

The combination of a zeolite rotor and catalytic combustion technology demonstrates highly efficient and flexible waste gas treatment capabilities, making it suitable for a wide range of exhaust gas types. Next, we will explore in detail the specific types of exhaust gases it can handle.

- Volatile Organic Compounds (VOCs) Emissions: Zeolite rotor technology demonstrates excellent adsorption capacity for VOC-laden waste gases, effectively separating them from the exhaust stream. During the catalytic combustion stage, the adsorbed VOCs are completely oxidized at relatively low temperatures, converting them into harmless substances such as carbon dioxide and water. This technology is particularly suitable for treating VOC emissions from industries such as petrochemicals, printing, coating, and automotive spray painting.

- Odorous Gases: Zeolite rotors also exhibit high adsorption efficiency for malodorous gases like hydrogen sulfide and ammonia. Through catalytic combustion, these foul-smelling gases are effectively decomposed, achieving deodorization. This method is widely applied in waste incineration, sewage treatment, livestock farming, and other industries requiring odor control.

- Hazardous Gase: For harmful gases such as carbon monoxide and nitrogen oxides, zeolite rotors can adsorb and subsequently convert them via catalytic combustion. This technology offers significant advantages in treating automotive exhaust and industrial furnace flue gases.

- Smoke and Particulate Matter: The combination of zeolite rotor and catalytic combustion technology can also be applied to treat smoke and particulate emissions. Through synergistic action, this method effectively reduces hazardous components in smoke to meet emission standards, making it suitable for industries with high particulate emissions, such as coal-fired power plants and steel mills.

- Other Organic Compounds: Persistent organic pollutants like polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs) can also be efficiently adsorbed by zeolite rotors and decomposed during catalytic combustion.

- Low-Concentration Industrial VOC Emissions: For industrial waste gases containing low VOC concentrations, this technology maintains high efficiency and environmental friendliness. The zeolite rotor’s adsorption effect concentrates organic compounds in the exhaust stream, reducing energy consumption in subsequent treatment, while catalytic combustion ensures complete decomposition for harmless emission.

In summary, the combination of a zeolite rotor and catalytic combustion technology holds broad application prospects and significant environmental importance in the field of waste gas treatment.